Flat End Mill Vs Ball End Mill . A ball nose end mill has a. Ball end mills have rounded tips and are used to mill 3d shapes or rounded grooves. Ball nose end mills are ideal for. The main difference between a ball nose end mill and a flat end mill is the shape of their cutting heads. For fast cuts and the greatest rigidity, use shorter end mills with larger diameters. Because end mills can have a wide variety of different specifications, it would be best for your understanding if i explained each type of end mill, such as flat end mills versus round nose mills versus ball end mills, separately. Variable helix end mills reduce. From one end mill to the next, the most obvious difference you will find is that end mills come in many shapes and sizes. Toolpath strategies are tailored to the specific capabilities and characteristics of ball nose and flat end mills.

from kxmachining.com

Because end mills can have a wide variety of different specifications, it would be best for your understanding if i explained each type of end mill, such as flat end mills versus round nose mills versus ball end mills, separately. Toolpath strategies are tailored to the specific capabilities and characteristics of ball nose and flat end mills. From one end mill to the next, the most obvious difference you will find is that end mills come in many shapes and sizes. Ball nose end mills are ideal for. Variable helix end mills reduce. The main difference between a ball nose end mill and a flat end mill is the shape of their cutting heads. A ball nose end mill has a. Ball end mills have rounded tips and are used to mill 3d shapes or rounded grooves. For fast cuts and the greatest rigidity, use shorter end mills with larger diameters.

How many tools are used in CNC machining in 2022 kxmachining

Flat End Mill Vs Ball End Mill Ball nose end mills are ideal for. Ball nose end mills are ideal for. Ball end mills have rounded tips and are used to mill 3d shapes or rounded grooves. A ball nose end mill has a. For fast cuts and the greatest rigidity, use shorter end mills with larger diameters. Toolpath strategies are tailored to the specific capabilities and characteristics of ball nose and flat end mills. Variable helix end mills reduce. From one end mill to the next, the most obvious difference you will find is that end mills come in many shapes and sizes. The main difference between a ball nose end mill and a flat end mill is the shape of their cutting heads. Because end mills can have a wide variety of different specifications, it would be best for your understanding if i explained each type of end mill, such as flat end mills versus round nose mills versus ball end mills, separately.

From huanatools.com

Flat End Mills VS Round Nose Mills VS Ball End Mills Huana Tools Flat End Mill Vs Ball End Mill From one end mill to the next, the most obvious difference you will find is that end mills come in many shapes and sizes. A ball nose end mill has a. Ball nose end mills are ideal for. For fast cuts and the greatest rigidity, use shorter end mills with larger diameters. The main difference between a ball nose end. Flat End Mill Vs Ball End Mill.

From fabacademy.org

Bramwel Olela Flat End Mill Vs Ball End Mill Ball end mills have rounded tips and are used to mill 3d shapes or rounded grooves. A ball nose end mill has a. Because end mills can have a wide variety of different specifications, it would be best for your understanding if i explained each type of end mill, such as flat end mills versus round nose mills versus ball. Flat End Mill Vs Ball End Mill.

From www.youtube.com

Differences between Drilling and End Milling (Drill Vs End Mill) YouTube Flat End Mill Vs Ball End Mill Toolpath strategies are tailored to the specific capabilities and characteristics of ball nose and flat end mills. Ball nose end mills are ideal for. From one end mill to the next, the most obvious difference you will find is that end mills come in many shapes and sizes. Because end mills can have a wide variety of different specifications, it. Flat End Mill Vs Ball End Mill.

From mandmsales.net

7 Tips for Choosing the Right End Mill for the Job M & M Sales Flat End Mill Vs Ball End Mill Ball nose end mills are ideal for. Variable helix end mills reduce. Because end mills can have a wide variety of different specifications, it would be best for your understanding if i explained each type of end mill, such as flat end mills versus round nose mills versus ball end mills, separately. From one end mill to the next, the. Flat End Mill Vs Ball End Mill.

From www.harveyperformance.com

The Anatomy of an End Mill In The Loupe Flat End Mill Vs Ball End Mill The main difference between a ball nose end mill and a flat end mill is the shape of their cutting heads. Variable helix end mills reduce. From one end mill to the next, the most obvious difference you will find is that end mills come in many shapes and sizes. Ball end mills have rounded tips and are used to. Flat End Mill Vs Ball End Mill.

From huanatools.com

Flat End Mills VS Round Nose Mills VS Ball End Mills Huana Tools Flat End Mill Vs Ball End Mill A ball nose end mill has a. Because end mills can have a wide variety of different specifications, it would be best for your understanding if i explained each type of end mill, such as flat end mills versus round nose mills versus ball end mills, separately. Ball end mills have rounded tips and are used to mill 3d shapes. Flat End Mill Vs Ball End Mill.

From www.youtube.com

Indexable ball end mill for finishing ABPF[English Subtitles] YouTube Flat End Mill Vs Ball End Mill From one end mill to the next, the most obvious difference you will find is that end mills come in many shapes and sizes. For fast cuts and the greatest rigidity, use shorter end mills with larger diameters. Because end mills can have a wide variety of different specifications, it would be best for your understanding if i explained each. Flat End Mill Vs Ball End Mill.

From endof-storyy.blogspot.com

Bull Nose End Mill Definition End of Story Flat End Mill Vs Ball End Mill Variable helix end mills reduce. For fast cuts and the greatest rigidity, use shorter end mills with larger diameters. Toolpath strategies are tailored to the specific capabilities and characteristics of ball nose and flat end mills. Ball end mills have rounded tips and are used to mill 3d shapes or rounded grooves. Ball nose end mills are ideal for. The. Flat End Mill Vs Ball End Mill.

From www.lathematters.com

Face Mill vs. End Mill Main Differences Explained! Flat End Mill Vs Ball End Mill Toolpath strategies are tailored to the specific capabilities and characteristics of ball nose and flat end mills. From one end mill to the next, the most obvious difference you will find is that end mills come in many shapes and sizes. Because end mills can have a wide variety of different specifications, it would be best for your understanding if. Flat End Mill Vs Ball End Mill.

From www.zandtools.com

5 Popular Types of End Mills CNC Tools Zand Tools Flat End Mill Vs Ball End Mill Toolpath strategies are tailored to the specific capabilities and characteristics of ball nose and flat end mills. The main difference between a ball nose end mill and a flat end mill is the shape of their cutting heads. Ball nose end mills are ideal for. Ball end mills have rounded tips and are used to mill 3d shapes or rounded. Flat End Mill Vs Ball End Mill.

From engineeringlearn.com

Types of Milling Cutter Tools and Their Uses [with Pictures Flat End Mill Vs Ball End Mill A ball nose end mill has a. For fast cuts and the greatest rigidity, use shorter end mills with larger diameters. Ball nose end mills are ideal for. Because end mills can have a wide variety of different specifications, it would be best for your understanding if i explained each type of end mill, such as flat end mills versus. Flat End Mill Vs Ball End Mill.

From www.speedtigertools.com

End Mill Cutting & End Milling Technical Guide Flat End Mill Vs Ball End Mill From one end mill to the next, the most obvious difference you will find is that end mills come in many shapes and sizes. Because end mills can have a wide variety of different specifications, it would be best for your understanding if i explained each type of end mill, such as flat end mills versus round nose mills versus. Flat End Mill Vs Ball End Mill.

From www.researchgate.net

General tool geometry and surfaces of the various end mills. a General Flat End Mill Vs Ball End Mill A ball nose end mill has a. Toolpath strategies are tailored to the specific capabilities and characteristics of ball nose and flat end mills. For fast cuts and the greatest rigidity, use shorter end mills with larger diameters. From one end mill to the next, the most obvious difference you will find is that end mills come in many shapes. Flat End Mill Vs Ball End Mill.

From www.aliexpress.com

Free Shipping Solid Carbide Flat End Mill High precision Milling Flat End Mill Vs Ball End Mill Because end mills can have a wide variety of different specifications, it would be best for your understanding if i explained each type of end mill, such as flat end mills versus round nose mills versus ball end mills, separately. Variable helix end mills reduce. From one end mill to the next, the most obvious difference you will find is. Flat End Mill Vs Ball End Mill.

From www.mscdirect.com

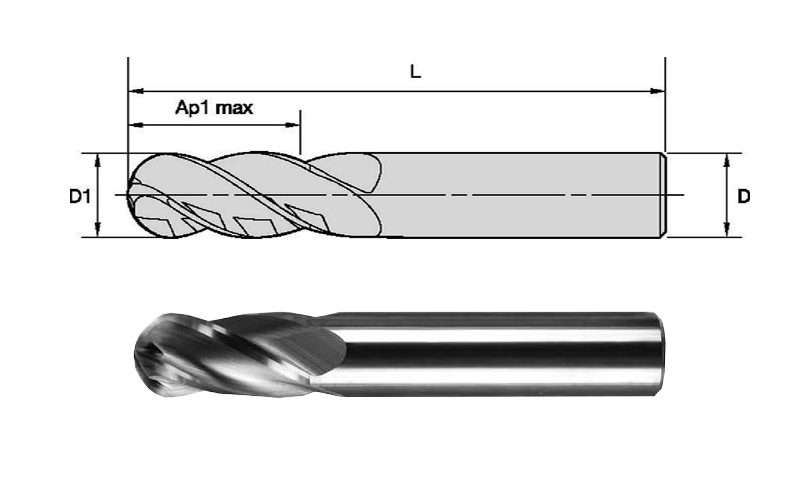

Kennametal Ball End Mill 3/8" Dia, 11/4" LOC, 4 Flute, Solid Flat End Mill Vs Ball End Mill The main difference between a ball nose end mill and a flat end mill is the shape of their cutting heads. A ball nose end mill has a. Ball end mills have rounded tips and are used to mill 3d shapes or rounded grooves. For fast cuts and the greatest rigidity, use shorter end mills with larger diameters. Ball nose. Flat End Mill Vs Ball End Mill.

From docs.fabctory.com

Frese e Strumenti · Introduzione alla fresatura CNC Flat End Mill Vs Ball End Mill Variable helix end mills reduce. The main difference between a ball nose end mill and a flat end mill is the shape of their cutting heads. Ball nose end mills are ideal for. Toolpath strategies are tailored to the specific capabilities and characteristics of ball nose and flat end mills. Ball end mills have rounded tips and are used to. Flat End Mill Vs Ball End Mill.

From www.hgt-endmills.com

Ball End Mill Magic Cutting Series HG TECHNOLOGY CO., LTD Flat End Mill Vs Ball End Mill Ball nose end mills are ideal for. A ball nose end mill has a. For fast cuts and the greatest rigidity, use shorter end mills with larger diameters. From one end mill to the next, the most obvious difference you will find is that end mills come in many shapes and sizes. Variable helix end mills reduce. Toolpath strategies are. Flat End Mill Vs Ball End Mill.

From www.cnccookbook.com

Ball Nose End Mill [Easy Guide to Ball Cutters] CNCCookbook Be A Flat End Mill Vs Ball End Mill The main difference between a ball nose end mill and a flat end mill is the shape of their cutting heads. A ball nose end mill has a. For fast cuts and the greatest rigidity, use shorter end mills with larger diameters. From one end mill to the next, the most obvious difference you will find is that end mills. Flat End Mill Vs Ball End Mill.